|

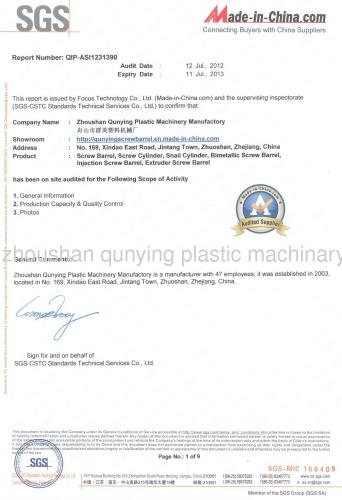

Zhoushan Qunying Plastic Machinery Manufactory

|

| Price: | 1000.0~20000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Conical Parallel twin screw barrel for extruder machines

The Specification of Conical twin screw and barrel

Specification (d/D) | Work Length (mm) | Extruding Ability KG/H) | Screw Speed (rmp) |

Φ25/Φ53 | 540 | 25-40 | 5-50 |

Φ35/Ø77 | 810 | 40-70 | 5-50 |

Φ45/Φ90 | 990 | 50-80 | 5-45 |

Φ50/105 | 1070 | 100-150 | 4-45 |

Φ51/105 | 1220 | 100-150 | 4-40 |

Φ55/Φ110 | 1220 | 120-180 | 4-40 |

Φ60/Φ125 | 1320 | 150-200 | 4-40 |

Φ65/Φ120 | 1440 | 200-250 | 4-40 |

Φ65/Φ132 | 1440 | 200-250 | 4-40 |

Φ70/Φ140 | 1460 | 250-320 | 4-35 |

Φ75/Φ150 | 1480 | 300-360 | 4-35 |

Φ80/Φ143 | 1800 | 300-360 | 4-35 |

Φ80/Φ156 | 1660 | 300-360 | 4-35 |

Φ90/Φ184 | 2000 | 400-500 | 3-35 |

The Specification of Paralle twin screw barrel :

Φ50/2 | Φ65/2 | Φ80/2 | Φ90/2 | Φ105/2 |

Φ125/2 | Φ130/2 | Φ150/2 | Φ180/2 | Φ200/2 |

Advantages of machine reciprocating conical screw barrel with conical type:

1.Advanced Nitriding Technology

2.Anti-corrosion and Wear-resisting Duplex Metal Spraying Technoloy

SJSZ Bimetallic twin conical screw and barrel

For good plasticizing effect,we have different designs of twin conical screw and barrel for extruder machine to meet customer's demand.

Techincal Advantages of twin parallel screw barrel for compounding machine :

1.Advanced Nitriding Technology

2.Anti-corrosion and Wear-resisting Duplex Metal Spraying Technoloy

3.We use special alloy powders being sprayed and welded on the screw's ridge,and

use different alloy and welding methods for the screw of different functions.

Especially application:

Rubber,various high glass fiber, mineral fiber and PPA,PPS, PA6T, LCP,VO fire protection, ferrous power, magnetic powder and etc. Meanwhile,Used for PVC + 30% CaCo3, recylced plastic material,etc Product Parameter: Product SJSZ Bimetallic twin conical screw and barrel Hardness after hardening and tempering HB260°~320° Nitrided Hardness HV950°~1000° Nitrided Depth 0.50~0.7mm Nitrided Brittleness above 2 stage Surface Roughness Ra0.4 Screw straightness 0.015mm Hardess of surface chromium-plating after Nitriding HV≥950HV Chromium-plating Depth 0.05~0.10mm ALLoy Depth 0.8~2.0mm Alloy hardness HRC56°~65° Alloy iron,nickel,tungsten,molybdenum Types of screw Gradual type,mutant type,wave type,barrier type,double screen type,shunt type,separation type,exhaust type,pin type,mixed type,double-head type,three-head type,multi head type etc.