|

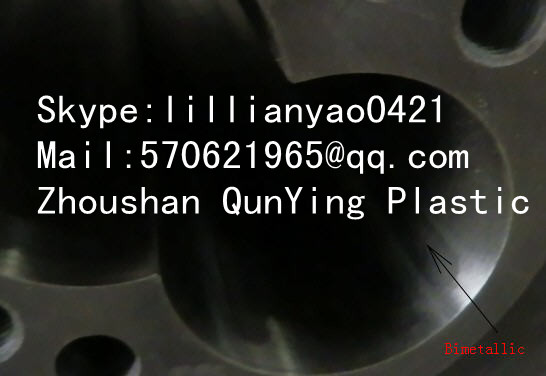

Zhoushan Qunying Plastic Machinery Manufactory

|

| Price: | 1000.0~20000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Specification (d/D) | Work Length (mm) | Extruding Ability KG/H) | Screw Speed (rmp) |

Φ25/Φ53 | 540 | 25-40 | 5-50 |

Φ35/Ø77 | 810 | 40-70 | 5-50 |

Φ45/Φ90 | 990 | 50-80 | 5-45 |

Φ50/105 | 1070 | 100-150 | 4-45 |

Φ51/105 | 1220 | 100-150 | 4-40 |

Φ55/Φ110 | 1220 | 120-180 | 4-40 |

Φ60/Φ125 | 1320 | 150-200 | 4-40 |

Φ65/Φ120 | 1440 | 200-250 | 4-40 |

Φ65/Φ132 | 1440 | 200-250 | 4-40 |

Φ70/Φ140 | 1460 | 250-320 | 4-35 |

Φ75/Φ150 | 1480 | 300-360 | 4-35 |

Φ80/Φ143 | 1800 | 300-360 | 4-35 |

Φ80/Φ156 | 1660 | 300-360 | 4-35 |

Φ90/Φ184 | 2000 | 400-500 | 3-35 |

Material | 38 38CrMoALA,SKD61,D2 etc. |

Hardness After Hardening&Tempering | HB260-290 |

Depth of Nitrided | 0.5-0.8mm |

Hardness of The Surface | Hv950-1100 |

Surface Roughness | Ra0.4um |

Linearity of Screw | 0.015mm/m |

| Technical Parameter | |

Base Material | 1)38CrMoAlA(JIS SACM645);2)Cr12MOV(JIS SKD-11) ; 3)4Cr5MoSiV1(JIS SKD-61) ;4)42CrMo(AISI 4140) |

| Bimetallic Alloy Materials | 1)Fe-based alloy 2)Ni-based alloy/Deloro alloy 3)Co-based alloy 4)NiCo-based alloy 5)Tungsten carbide/Wolfram carbide |

| Double-alloy level | Level A - containing Tungsten of 40% Level B - containing tungsten of 25% Level C - containing tungsten of 15% |

| Surface Treatment | Heat Treatment High Frequency Treatment Nitriding treatment(120 Hours): Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: 900-1020Hv (HRC56°-65°) Hard Chrome Plating treatment: Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: ≥950HV Nickel alloy plating.treatment: Bimetallic Barrel/Cylinder: Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55°-72° Spraying corrosion wear-resisting dual metal layers |

| Basic information | Roughness of the surface:Ra0.4um Linearity of the screw: ≤0.015mm Linear axis limit: ≤0.02mm Hardness after Hardening & Tempering: HB240-280 Fragility of Nitration:≤Two class |

| Material Application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap or Granule), PVC + 30% CaCo3, etc |