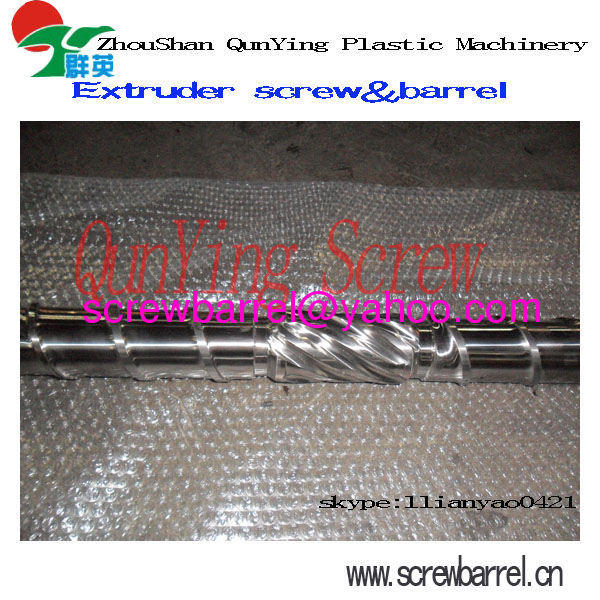

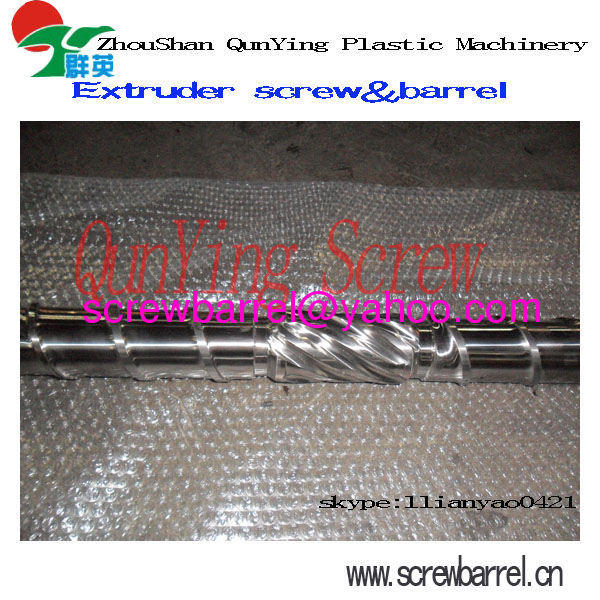

bimetallic mixing screw head

| Price: |

100.0~10000.0 USD |

| Payment Terms: |

T/T,L/C,WU |

| Place of Origin: |

Zhejiang, China (Mainland) |

Product Detail

Model No.:

QY-ES02

Production Capacity:

1000 sets per month

Delivery Date:

25 Days

Brand Name:

QunYing

Base Material:

38CrMoAlA,DC5,D2,SACM645,ec...

Application 1:

Injection Moulding Machines

Bimetallic Screw Process:

Spray Welding

Bimetallic Depth:

2~4mm

Capacity of Injection:

10G~30000G

Means of Transport:

Ocean,Land,Air

Packing:

Wooden Case (Exported Stand...

Shaft Design:

Single

Power:

14-200KW

Bimetallic Grade:

Grade A/B/C

Application 2:

ABS,PVC,PP/PE,PET,Engineeri...

Bimetallic Barrel Process:

Centrifuge Casting

Hardness:

Above HRC65

Power of Locknut:

100KN-3500KN

1.bimetallic mixing screw head

2.bimetallic/nitided

3.For extruder

4.Can be customized

5.ISO/SGS approved

Extruder screw barrel with bimetallic mixing screw head for PVC

We are in the China's Screw Town-Jingtang Town in Zhoushan City, and we are one of the biggest factory here with more than 15 years experience.

All our screws&barrels are in high quality,woderful design and competive price.

The picture you click is our extruder barrels, (but we also produce injection screw barrel,

blowing machine screw barrel, rubber

machine screw barrel, conical

twin screw barrel,

parallel twin screw barrel and ext.) About the

extruder screw barrel,the specifications and technical dates are list at following:

Specifications:

Single

screw and barrel for extruders

Screw Diameter:20-500mm

Maximun screw length: 10000mm

Barrel inner bore dia500mm

Technical dates:| Hardness after Hardning&tempering: | HB280-320 |

| Nitrided Hardness: | HV850-1000 |

| Nitrided Case Depth: | 0.5-0.8mm |

| Nitrided Brittleness: | Less than Grade 1 |

| Surface Roughness: | Ra 0.4 um |

| Screw Straightness: | 0.015mm |

| Surface Chromium-plating's Hardness after Nitriding: | ≥900HV |

| Chromium-plating Depth: | ~0.20mm |

| Alloy Hardness: | HRC56-68 |

| Alloy Depth: | 0.8~2.0mm |

| Bimetallic Hardness: | HV950-1100 |

| Bimetallic Depth: | 1.5mm~4mm |

Our

screw barrel can ensure the well performance and low energy consumption of extruder and

Injection molding machine.

We insist on the principle of quality first, honest to customers, the quickest service for customers" to improving us, our goal is to satisfy our customers.

About QunYing:

- Our Strength: We have an experience of more than many year of manufacturing and designing Plastic machines, varied Screws and Barrels and spares. We concentrate on improving quality, updating design and enhancing service.

- Our products: Screws Barrels for Injection, Extrusion, and Blow Molding applications; relevant accessories(such as die head, gearbox, filter screen changer and so on); plastic processing machinery.

- Location advantage: located in China's Screw Town - Jintang Town in Zhoushan City, near to Ningbo Port and Shanghai Port.

- Market areas: global sales network reaching South America, Eastern Europe, Southeast Asia, Africa, Oceania and the Middle East.

- We promise: We assure the customer benefits, We provide competitive price, We Emphasis On Cooperation.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com